Products

-

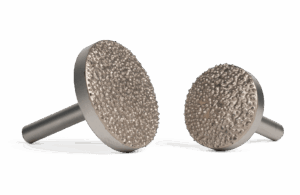

Stump Grinder Sharpening Tools

Price range: $154.95 through $169.95 Select options This product has multiple variants. The options may be chosen on the product page -

Chipper Blade Sharpening Tools

Price range: $149.95 through $164.95 Select options This product has multiple variants. The options may be chosen on the product page -

Sharpening Tool Combo Pack

$215.95 Add to cart -

Industrial Mower Blade Sharpening Tool

Price range: $134.95 through $149.95 Select options This product has multiple variants. The options may be chosen on the product page